Accidents sometimes happen – in food processing operations just like everywhere else, a bottle or glass jar falls from the production line, off a conveyor belt or out of the packaging, and smashes on the floor.

This has to be dealt with – and not just in any old way.

Solution We can Offer :

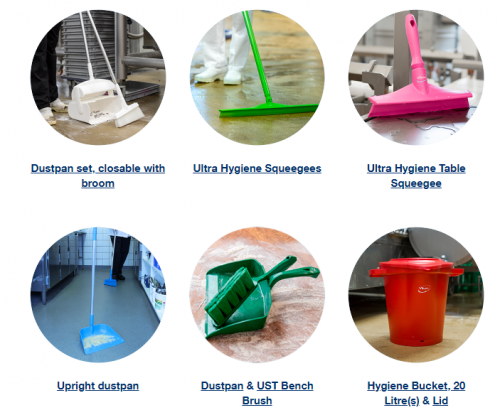

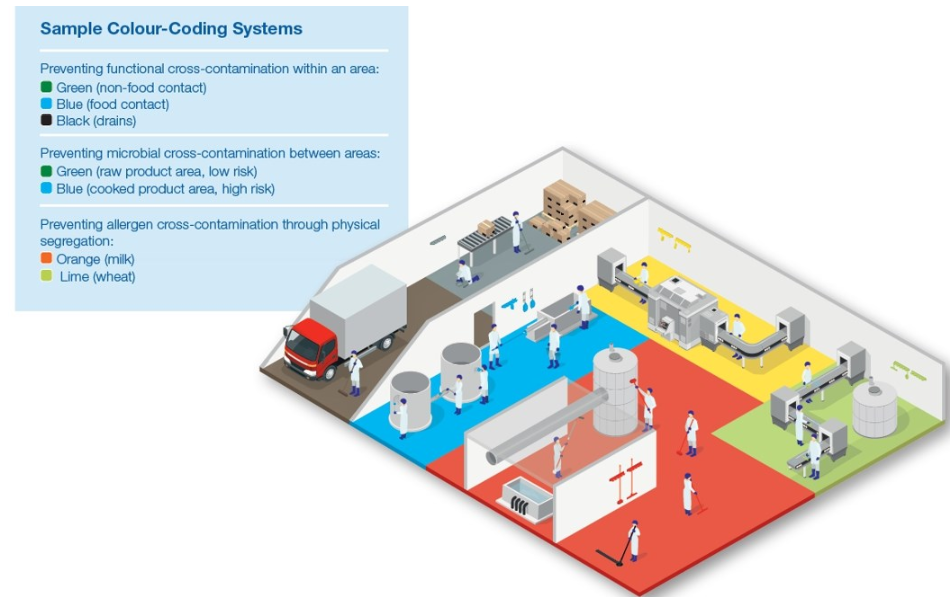

- The selection, use, maintenance and storage of dedicated, identifiable, colour-coded cleaning equipment for food container breakages

- The selection of dedicated, accessible, closable/lidded, colour-coded waste containers for collecting debris from food container breakages.

Some tips Our Vikan experts normally suggest;

- Choose a unique colour for tools associated with cleaning up glass debris – it should be a colour that is not used for any other purpose anywhere at the site. It’s usually also a good idea to select a colour with a high, obvious signal factor, such as orange or pink.

- Keep the items in, or close to, the area of risk so they are easily available when breakages occur.

Keep the items well away from other cleaning equipment to prevent any risk of cross-contamination. The best thing is to have a separate container (such as a Vikan bucket with lid) into which any stray pieces of glass can be placed. - There should also be agreed routines for emptying and cleaning this container and the glass breakage cleaning equipment, regularly.

- Use a mobile shadowboard on which to place the tools, and keep them in order. Such a board is easy to roll out when an accident takes place.

Be prepared for accidents!

<

<