Restaurants, bars, cafes, contract catering and food services providers have been some of the hardest hit by the current Covid-19 global pandemic. Many have been forced to close their operations and now await further advice on when and how they should re-open

When they do there will be many things to consider, including how to ensure food safety and control Covid-19 in relation to both their staff and customers.

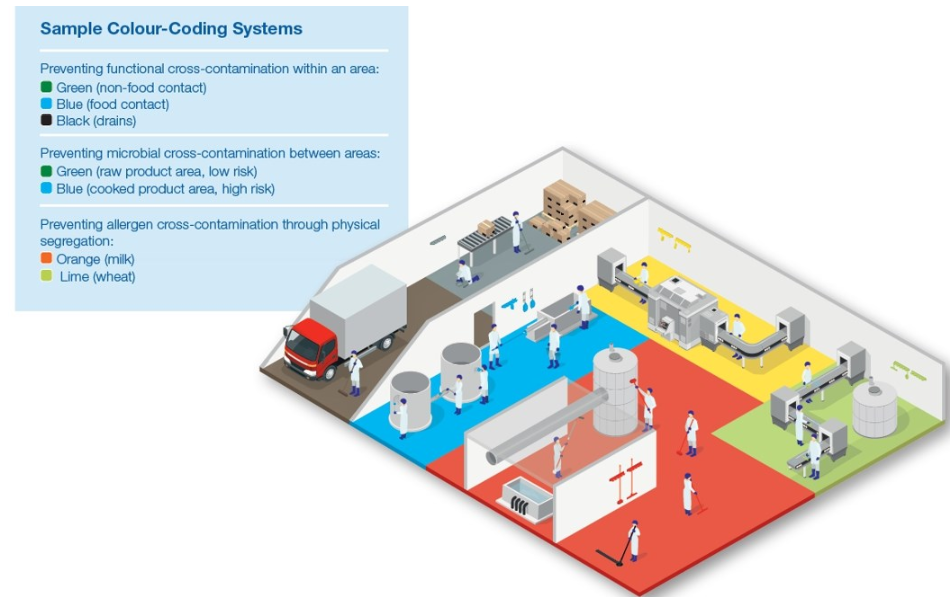

See article below :