HFiltrasi merancang solusi khusus sesuai dengan polutan hingga ukuran scrubber yang akan dipasang.

Pengalaman bertahun-tahun memungkinkan kami menciptakan sistem khusus untuk setiap pelanggan, benar-benar berguna, valid, dan fungsional. Kami tidak ingin membuat pembaca kami bosan dengan gagasan dan perhitungan teoritis, jadi kami memilih untuk membawa pengalaman kami, menceritakan bagaimana kami sampai pada desain venturi scrubber untuk pelanggan kami Tempra 3000

Scrubber venturi untuk Tempra 3000

HFiltrasi telah berkolaborasi dengan perusahaan Italia, Tempra 3000, yang mengkhususkan diri dalam realisasi perawatan atmosfer termal dan terkontrol, merancang venturi scrubber ad hoc.

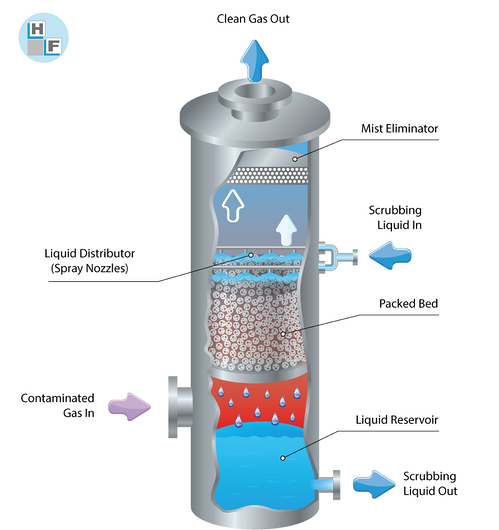

Scrubber jenis ini adalah sistem penyaringan yang memungkinkan untuk mengurangi konsentrasi senyawa organik yang mudah menguap dan debu yang ada dalam aliran gas, dan hanya dapat digunakan ketika polutan yang akan dihilangkan bereaksi dengan air.

Pengurangan ini pada dasarnya terjadi karena proses dampak antara cairan pencuci yang dinebulasi dan polutan yang ada di udara. Yang kotor sebenarnya dimasukkan ke bagian bawah menara cuci dan didorong ke atas untuk dicuci melawan aliran balik, dengan kecepatan rendah dan pada permukaan kontak yang lebar.

Masalah yang ditemukan oleh pelanggan sebelum intervensi kami meliputi:

- Titik ekstraksi tidak mencukupi untuk pengerasan asap

- Garis perpipaan kompleks dengan titik akumulasi

- Tudung hisap berukuran kecil

- Sistem yang diinstal sebelumnya tidak mencukupi karena ukurannya terlalu kecil.

The scrubber venturi dirancang oleh HFiltration untuk Tempra 3000

HFiltrasi merancang scrubber venturi dengan laju aliran udara 34.000 m3/jam.

Teknisi kami telah menyederhanakan jalur perpipaan yang ada dan menghilangkan titik penumpukan debu. Mereka juga mengidentifikasi ukuran tudung hisap yang tepat berdasarkan laju aliran udara, mengoreksi kecepatan jalur pipa untuk menghindari sedimentasi, dan akhirnya membuat tudung hisap khusus tambahan untuk mengumpulkan asap yang mengeras.

Setelah instalasi, pelanggan dapat mengidentifikasi manfaat berikut:

- Pengurangan biaya pengoperasian, pemeliharaan, dan energi

- Penyederhanaan jalur perpipaan dan penghapusan titik penumpukan debu

- Kinerja tinggi dari tudung khusus untuk aspirasi asap yang mengeras

- Sistem berukuran tepat sesuai dengan struktur kompleks dan dengan aliran udara yang lebih tinggi

Scrubber dapat mengurangi senyawa organik volatil (VOC) dan konsentrasi debu yang ada dalam aliran gas. Ini digunakan bila ada zat yang akan dihilangkan yang mampu bereaksi dengan adanya air karena sebenarnya pengurangan terjadi melalui dampak antara washing liquid yang disemprotkan dan polutan.

Scrubber dapat mengurangi senyawa organik volatil (VOC) dan konsentrasi debu yang ada dalam aliran gas. Ini digunakan bila ada zat yang akan dihilangkan yang mampu bereaksi dengan adanya air karena sebenarnya pengurangan terjadi melalui dampak antara washing liquid yang disemprotkan dan polutan.

When you need to install a bag filter for dust abatement within a company, there are a series of parameters to consider in order to evaluate the most suitable model according to specific needs. .

When you need to install a bag filter for dust abatement within a company, there are a series of parameters to consider in order to evaluate the most suitable model according to specific needs. .