AIRCHOC® from Standard Industrie can effectively deal with clogging and concretions issues within your storage units: silos, hoppers, tanks. Clogging and concretions within your silos and hoppers can be efficiently solved by combining the power and innovation of the AIRCHOC®

PROCESS CENTRALE THERMIQUE

PARC

AIRCHOC : Unloading gantry hopper, coal hopper, chute

ASPI : Conveyor

LIFTUBE : Coal conveyor, bio mass

CHAUDIERE (tranche)

AIRCHOC : hopper and boiler feed chute

ASPI : Work floor, feed hopper, boiler, Grinder, electro-filter

LIFTUBE : Coal or bio mass conveyor

GIRONET : Coal hopper

GAS TREATMENT

AIRCHOC : Hopper under filter or electro-filter, ash silo

ASPI : Desulfurization workshop, electro filter ash silo

LIFTUBE : Little conveyor in this area, pneumatic transport

STEEL INDUSTRY PROCESS

DOCK (Port facility)

AIRCHOC : Discharge gate hopper (iron ore, coal)

VACUUM : conveyor

LIFTUBE : ore and fuel

PREPARATION OF CHARGES

AIRCHOC : Iron ore hopper

VACUUM : Work floor, conveyor, crusher, and elevator

LIFTUBE : feeding conveyor

GIRONET : ore hopper

COKE OVENS

AIRCHOC : Grinding workshop (if there is one) coal tower, coal car

VACUUM : work floor, conveyor, tower

LIFTUBE : coal conveyor

GIRONET : Coal tower

AGGLOMERATION

AIRCHOC : Ore silos and hoppers, limestone, coal, fine chipboard Filter hopper or electro-filter

VACUUM : Work floor, conveyor

LIFTUBE : Ore conveyor, limestone, coal, fine chipboard

GIRONET : Silos and hoppers

OBTURATOR : Filter or electro filter

BLAST FURNACE

AIRCHOC : hoppers but large particle size without too much problem. Filter hopper or electro-filter

VACUUM : Work floor

LIFTUBE : ore conveyor, agglomerate and coke

GIRONET : concrete accumulation

STEEL WORKS

AIRCHOC : Heat exchanger, gas cooling tower (quench) Filter hopper or electro filter, dust silo

VACUUM : Steel casting, filter or electrofilter

LIFTUBE : conveyor

GIRONET : Dust silo

OBTURATEUR : Filter

ANIMAL FEED

EPOL – PIETERMARITZBURG

AIRCHOC®

SOUTH AFRICA

Starting Date: 2021

APPLICATION

Bran.

PROBLEM

This cylindrical unit is equipped with a rectangular multiple screw discharger. In the transition section from round to rectangle above the discharger, bran build-ups occur on a regular basis to full blockage of the extraction and therefore the production output. Bridging occurs from the beginning of the cone to the discharge.

SOLUTION

4 x air cannons AIRCHOC® ref AC515SJP.

RESULT

STANDARD INDUSTRIE guaranteed that no blockages and bridging problems will occur as long as the AIRCHOC® is in use, according to the predetermined location and firing sequence. Since February 2021, the AIRCHOC® are in operation and providing good results. The customer is satisfied and has placed an order for an extra 12 x AIRCHOC® for a 4 compartment soya silo.

THERMAL POWER PLANT

ENCE MERIDA (ENCE group)

AIRCHOC®

Spain

Starting Date: 2019

APPLICATION

Vegetable material.

APPLICATION AREA

Boiler.

PROBLEM

This customer is facing clogging problems (bridgind) both in the feed chutes of the biomass boiler and in the hopper above the augers. This clogging is mainly due to the low density of the material and its moisture content.

SOLUTION

8 AIRCHOC® 0,5 liter air cannons were strategically installed on the chutes and 4 AIRCHOC® AC520 were placed on the hopper to prevent material deposits. All in ATEX zone 20 version.The hopper had to be reinforced with thicker sections due to the powerful firing of the AIRCHOC® AC520.

RESULT

This device allows the customer to maintain its production of 20 mega watt / hour.

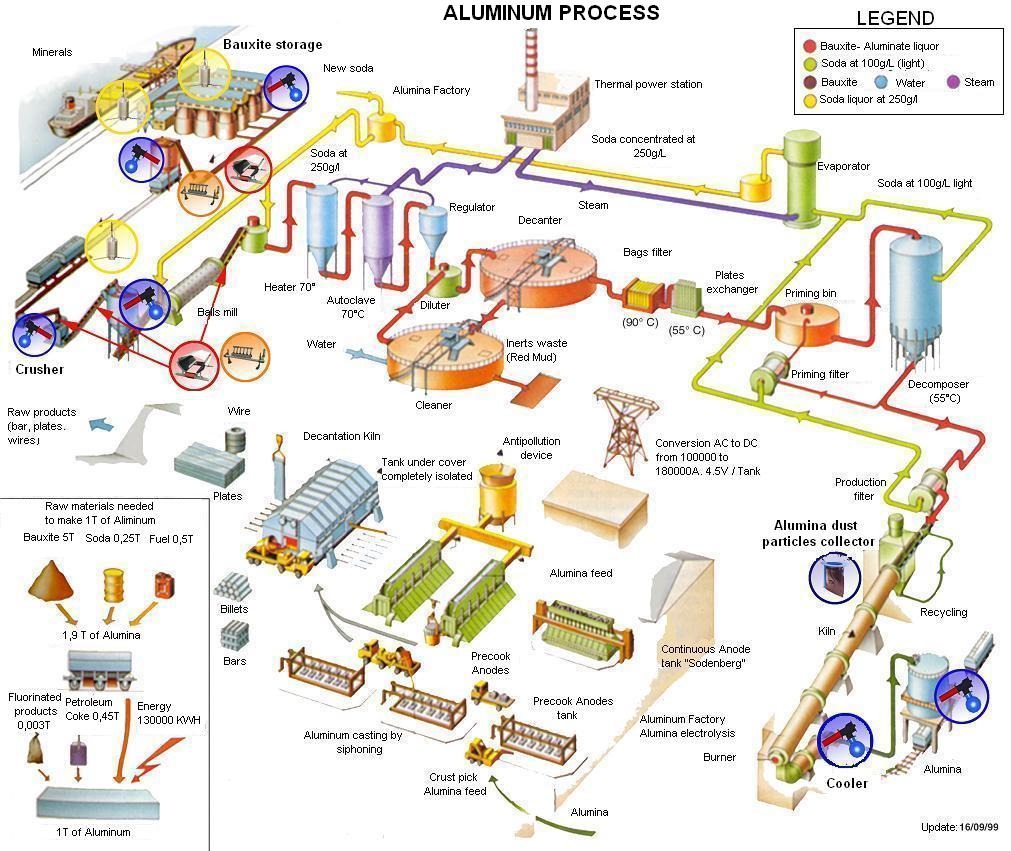

ALUMUNIUM PROCESS

SUGAR FACTORY

Do you want to learn more about our solutions?

Fill out our form below now and you will be contacted by one of our experts as soon as possible! You will have the opportunity to share all your needs. Fields marked with an asterisk are required!