Our Technology Partners

It is Europe’s largest industrial manufacturing company and a global leader in industrial automationand soware.

Rockwell Automation, Inc.is an American leader in industrial automation and digital transformation technologies.

It’s well-known brands include Allen-Bradley and FactoryTalk soware. Headquartered in Milwaukee, Wisconsin, USA. Rockwell Automation has 27,000 employees serving customers in over 100 countries.

Recognizing that some cases require alternative solutions, we also support automation systems from Japanese and Chinese brands.

SOLUTION & INDUSTRIES

INDUSTRIES

Oil & GAS

PETROCHEMICAL

PULP AND PAPER

COAL AND MINING

POWER PLANT

FOOD AND BEVERAGE

SOLUTIONS

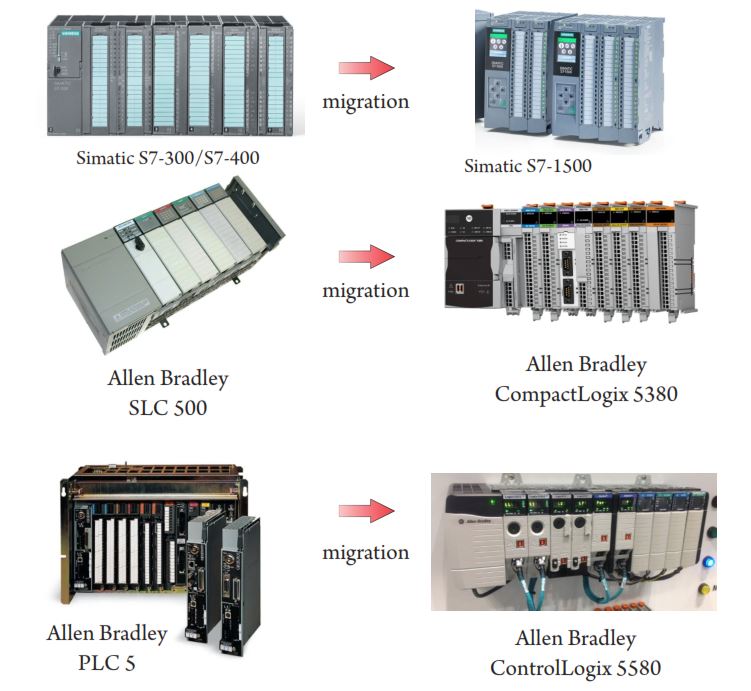

A. Migration Controller

With the Industrial Internet Of ings (IIOT) has becoming essential, automation systems must be updated for seamless IIOT integration.is requires upgrading the core of your automation control systems (controller).

Benefits of upgrading your controllers :

- Faster data processing

- Easier diagnostics

- Greater precision

- Cost effectiveness

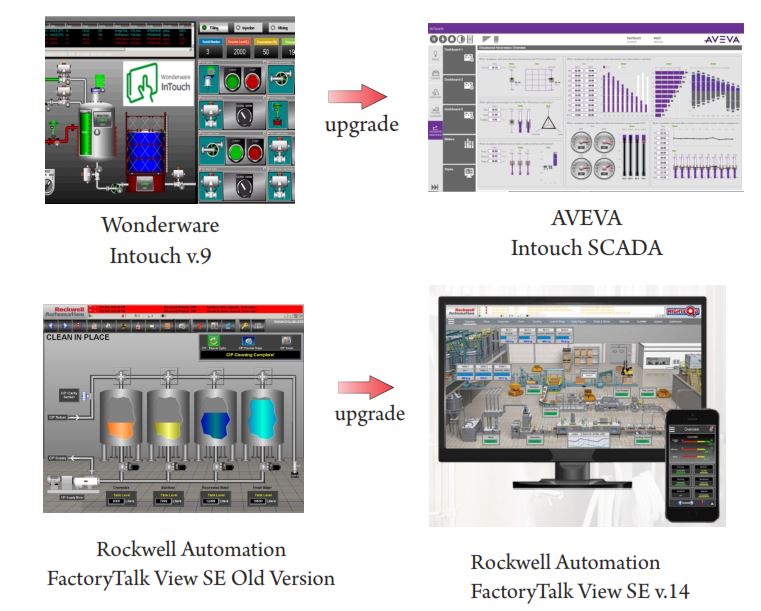

B. Human Machine Interface (HMI)

The Human Machine Interface (HMI) serves as a bridge between controllers and the operators. It allows operators to monitor internal processes and input necessary intructions. A well designed HMI is crucial for efficient operationsand production.

Six key benefits of modern HMI soware :

- Improved uptime and productivity

- Beer alarm management

- Enhance visuals and ease of use

- Instant access to critical information

- Faster system design and commisioning

- Secure and reliable operation

With advancements in display technology, modern HMIs offer signicantly improved feature compare to those from a decade ago.

C. Supervisory Control and Data Acquisition (SCADA)

SCADA systems enhance efficiency, safety, quality, and productivity, while also reducing operational costs, risks, and downtime in industrial control environments. Upgrading to the latest SCADA technology maximizesthe benefits in your control room.

Our engineers specialize in SCADA implementation using three major brands :

- WinCC by Siemens

- FactoryTalk View SE by Rockwell Automation

- Wonderware/AVEVA Intouch

D. Automation System Network Upgrade

Reliable and high speed data communication is critical for effecient industrial control sysmtes.

Upgrade your automation network system now to minimize unplanned downtime from daily operations and unexpected events while scaling for future needs. Experience the benefits instantly !

Our Switch Products :

- Unmanaged Switches

- Lightly Managed Switches

- High Performance Switches

Experience Project