ATEX certified industrial vacuum cleaners

DU-PUY is an expert manufacturer of a full range of ATEX-certified industrial vacuum cleaners, perfectly suited to construction needs to prevent the formation of ignition sources.

ATEX explosion-proof vacuum cleaners are essential for hazardous areas because they ensure the prevention of static electricity buildup. This is achieved through the use of components that enable effective ground discharge, such as antistatic filters, motors specially designed to prevent overheating, and accessories made of conductive materials.

The ATEX vacuum cleaner series offered by DU-PUY has been developed with specially designed components and accessories to ensure full compliance with ATEX regulations, as set forth in the European Union Directive 2014/34/EU.

ATEX zones are classified according to the presence of flammable gas or dust. Therefore, we offer ATEX-certified vacuum cleaners for work in environments classified as follows:

Zone 0 (gas) or Zone 20 (dust): for long-term activities where an explosive atmosphere is constantly present;

Zone 1 (gas) or Zone 21 (dust): for work areas where an explosive atmosphere consisting of air and flammable substances is likely to form;

Zone 2 (gas) or Zone 22 (dust): for environments where the formation of an explosive atmosphere occurs only for short periods.

By choosing ATEX vacuum cleaners from DU-PUY, you can ensure maximum safety and compliance in your operations in hazardous areas.

Contact us today for more information and advice from our experts.

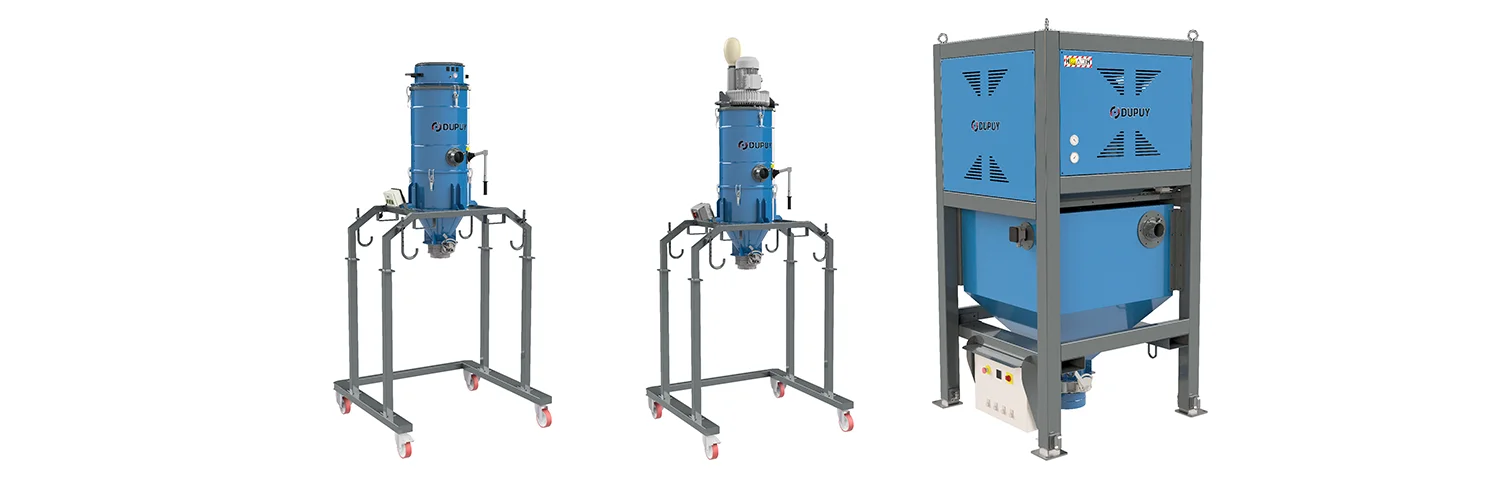

The ATEX range of vacuum cleaners

ATEX-certified vacuum cleaners offer a safe solution for industrial vacuuming in deflagration-prone environments.

ATEX certification requires rigorous safety systems, such as grounding, use of antistatic filters, certified motors, insulated electrical parts and a specially designed turbine suction body.

To operate in hazardous environments, it is essential to use industrial vacuum cleaners that meet the high safety standards required by ATEX certification. At DU-PUY, our experts are ready to provide advice and support to help you find the tailored vacuum solution that meets your security needs.

Rely on our industry experience and expertise to ensure a safe and compliant work environment.

Contact us today and find out how our ATEX-certified vacuum cleaners can contribute to your peace of mind and the protection of your work environment.

Our Solution Product

W3 AIR-EX 1/3D

W2 EX 1/3D

M70-90 ACD

M50 ACD

W2 MDI EX 1/2D

WD 3000 EX 1/3D

WD 3000 1/2D

W1 1/3D

W2 MDI EX 1/3D

WD 3000 ACD

Silofilter 200 Z22

Silofilter PN Z22

CVAC Z22 ATEX

W1 1/2D

W2 ACD

W2 1/3D

W2 1/2D

W2 Infini Z22 Atex certified industrial vacuum cleaner with turbine

W3 ACD

W3 1/3D

W3 1/2D

Silofilter 600-1000 Z22

W3 Infini ATEX

W 2 Infini ATEX

W2 MDI ACD

Serie M Z22

Bagfilter 160 Z22

WD 3000 AIREX 1/3D

W 3 AIR ATEX

WD 3000 AIREX 1/3D

W1 AIR-EX 1/3D

W1 AIR-EX 1/2D

W2 AIR Z22 Atex certified air operated industrial vacuum cleaner

W2 AIR-EX 1/2D – ATEX certified industrial compressed air vacuum cleaner

W3 AIR Z22 Compressed air vacuum cleaner

W3 AIR-EX 1/2D

Silovac 100T Z22