PCVAC - 7000

Vacuum unit PCVAC 7000 (Diesel)

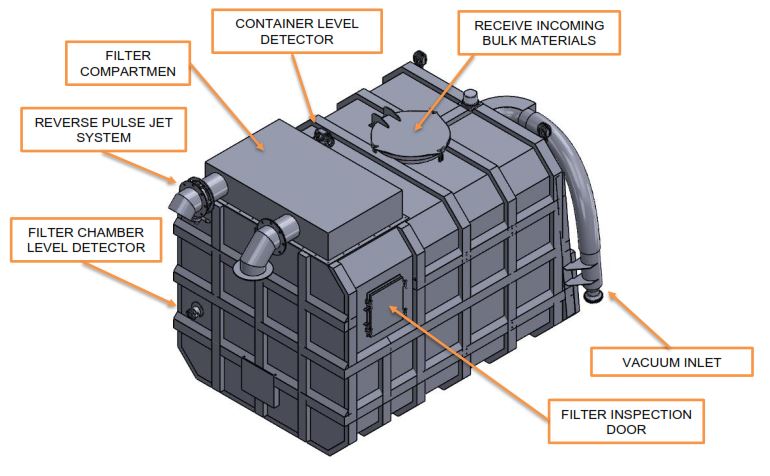

The PCVAC7000 suction unit is an apparatus for purely and typically industrial use, ideal for the aspiration of bulk and powder materials in large quantities through fixed or mobile pipes (hoses).

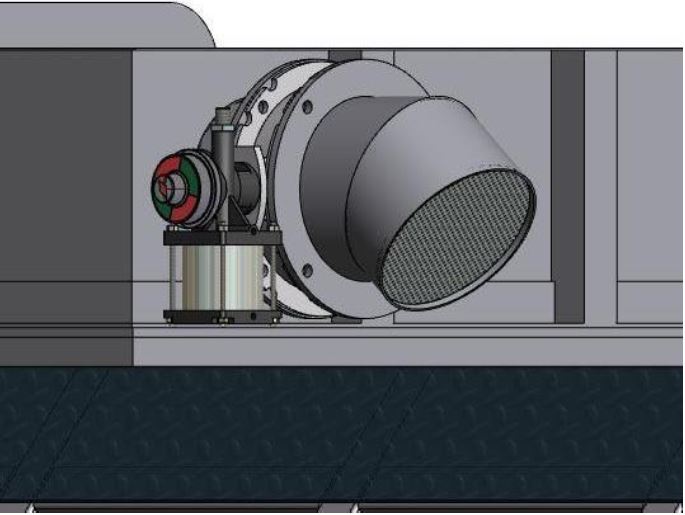

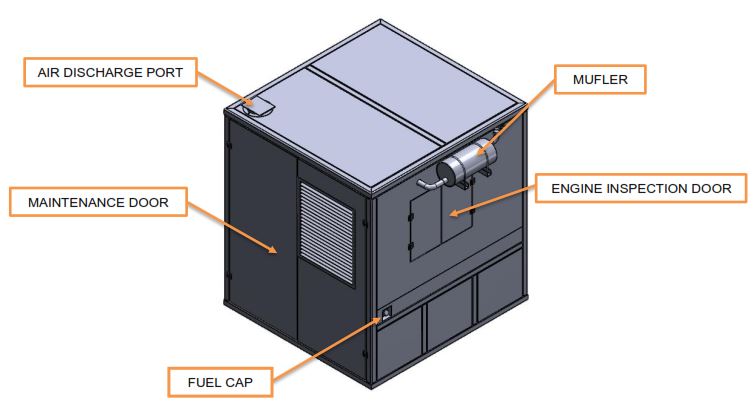

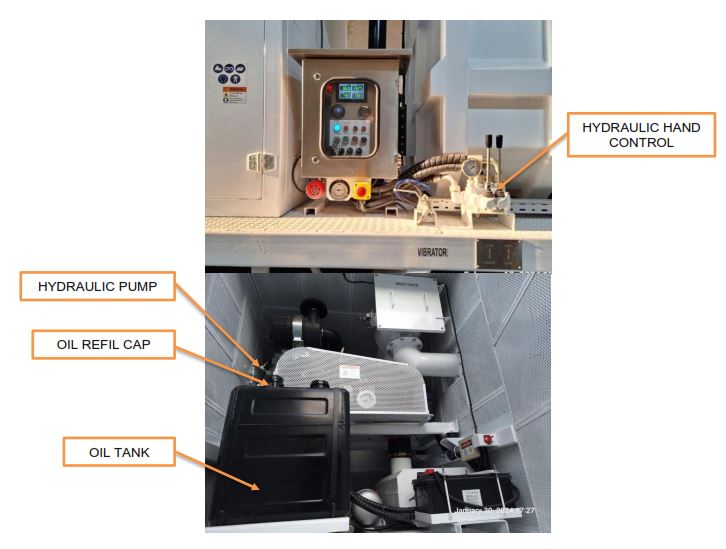

Performance is guaranteed through the use of a twin-screw positive-displacement pump. In order to guarantee the total protection of the working environment as well as the duration of the pump, the suction unit is equipped with a safety cartridge filter. The air, passing through the safety filter with cartridge and the silencer of the pump, is expelled into the atmosphere. The suction unit should be used with a suitable pre-separator to collect the dust and equipped with filters to stop the dust transported with the airflow. In case of a vacuum unit to be transported with a truck or trolley, the main filter should be inside the tank. The connection with the pre-separator is usually done by means of hoses and quick connectors. In case of a truck unit, the connection is done by means of automatic coupling connection. The pre-separator or tank is emptied through gravity through a rapid opening hatch below. The machine is independent from any connection when equipped with the diesel engine