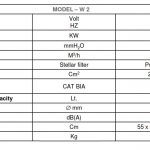

Product Description

Suction unit

The suction is provided by two by-pass motors, using carbon brushes, operated by indipendent switches and placed inside a sturdy steel casing. The motor head is filled with noise reducing material, in order to limit as much as possible the level of noise, and designed in order to convey the exhaust air towards the ground, so as not to bother the user and not to raise possible dust in the neighbouring area. The control board includes the two indipendent switches and a vacuum indicator with warning light, useful to detect possible clogging of the filter. Two handles placed on the sides enable an easy lifting and removal of the motor head for possible inspection or replacement of the underlying filter. The motor head is completed with a convenient cable support hook.

Filter unit

The filter is placed and protected inside the steel filter chamber; the filter is made of polyester, tailored with stars in order to increase the filter surface (2m2) and has a high filtration efficiency (3 micron). A manual filter shaker enables the user to clean the filter efficiently, by a vertical shaking movement, so as to detach most of the dust and mantain the filter clean, in order to increase its life and maintain the suction performance of the machine. The frontal aluminium die-cast suction inlet ( 50 mm. diameter), placed below the filter, makes it possible to vacuum at the same time dust, solid and liquid material (the latter only within the capacity of the container), with no need to change or take out the filter.

Reviews

There are no reviews yet.