The smallest man sweeper on board. Agile and powerful thanks to the cylindrical Ø265mm cylinder brush for 590mm in length and to the side brush Ø300mm. For a total workstation of 700mm. Easy to use with the handlebars and the removable waste collection drawer.

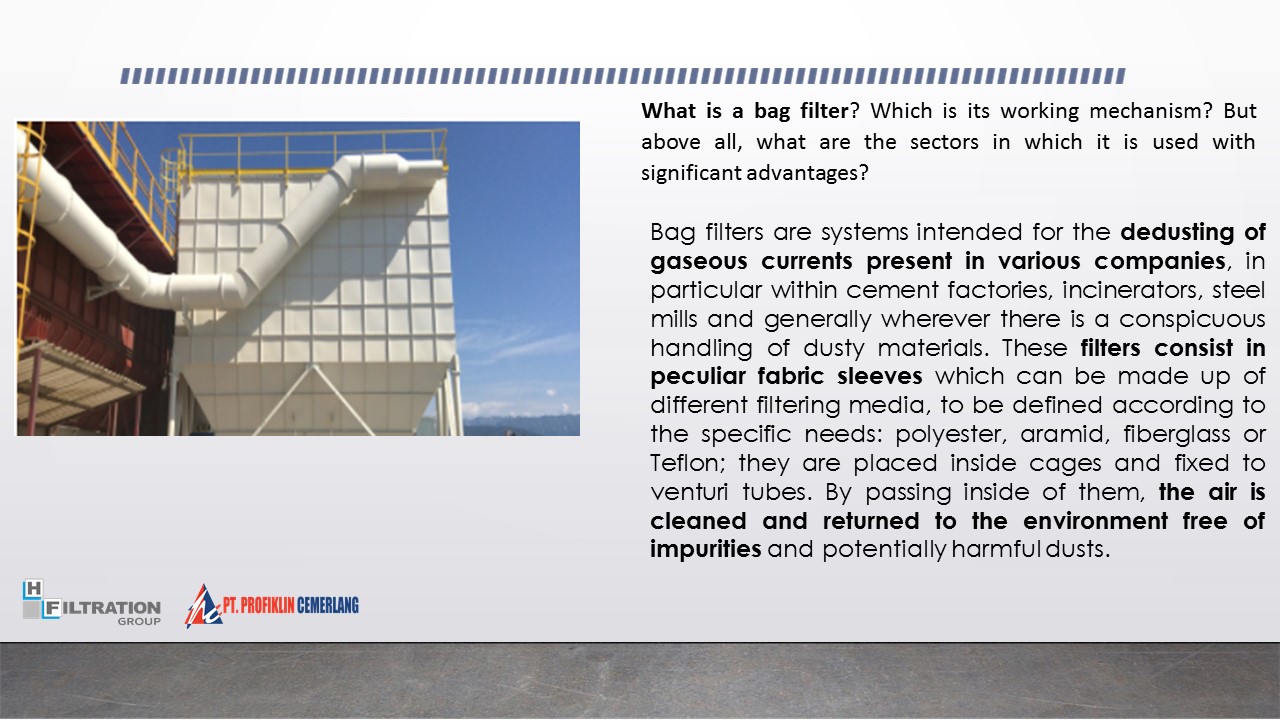

When you need to install a bag filter for dust abatement within a company, there are a series of parameters to consider in order to evaluate the most suitable model according to specific needs. .

When you need to install a bag filter for dust abatement within a company, there are a series of parameters to consider in order to evaluate the most suitable model according to specific needs. .

The Delux 50 E combination steam scrubbing machine is cable powered with a 5 litre solution tank capacity.

The Delux 50 E combination steam scrubbing machine is cable powered with a 5 litre solution tank capacity.